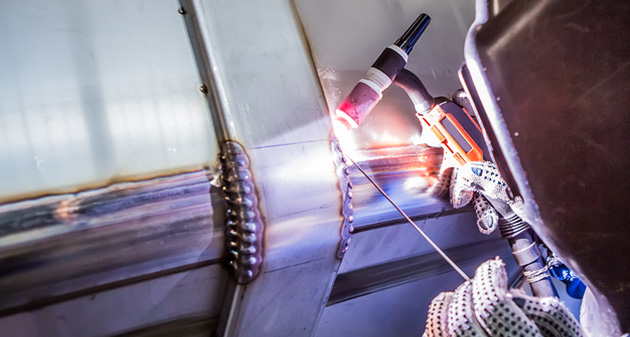

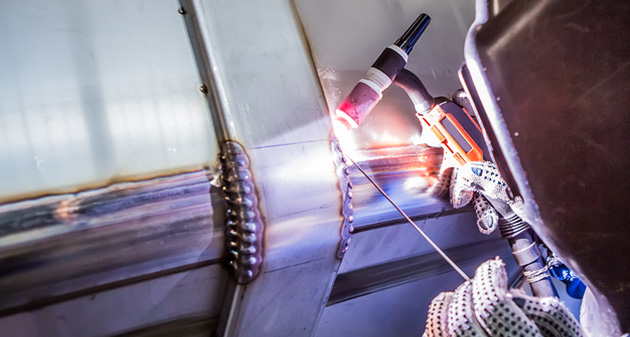

How to Choose the Right Welding Method for Stainless Steel

We all love stainless steel due to a wide range of benefits it offers. It can adapt its strength, workability and corrosion resistance. If you’re having trouble deciding between the right welding methods for stainless steel, you’ve come to the right place. In this article, we’ll be highlighting all the major welding methods that are being used largely for stainless steel. Whatever welding method you go with, make sure you’re using the right welding machine for stainless (ตู้ เชื่อม ส แตน เล ส, which is the term in Thai).

Let’s take a look at different welding methods:

Shielded Metal Arc Welding

This welding technique can be used to weld joints with thickness ranging from 0.05 inch to several inches. However you need to properly clean the welded area after each pass to avoid slag entrapment and porosity. Shielded metal arc welding is affordable and known for having low deposition rates,

Gas Metal Arc Welding

This method is an ideal option for long joints or for a huge amount of welds. GMAW has fast deposition rates, meaning you don’t need to take away slag between passes. However, it’s an expensive welding method due to its gear requirements.

Submerged Arc Welding

Submerged Arc Welding (SAW) is usually used to weld metal parts that are 0.5-inch thicker. It’s not suitable for austenitic stainless steel (without any ferrite), as it can cause cracks with heat. Monitoring welding conditions and choosing the right flux is vital for controlling ferrite content and deposit composition.

Before you try any of these methods, make sure you’re using the right welding machine. If you’re new at welding stainless steel, it’s important that you consult with experienced welding contractors to get the best advice.

What’s your take on this? Please feel free to share your thoughts in the comment section below.

My name is Wilson Michel. I post about home improvement ideas and how to make your home look beautiful and liveable. I hope my posts will help you with your DIY projects!